Business Challenges

- Reducing human intervention in processes

- Vision realisation

- Sourcing partner support

Keys to Success

- Prioritising software-based automation tech

- Siemens-provided software to boost efficiency

- Simulation optimisatin for digital twin

Results

- Launch benefits from automated processes

- Significant accomplishments in initiation

- YouniQ: Rapid, software-driven production

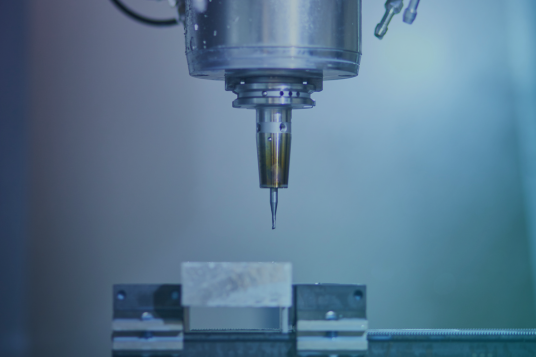

Case study YouniQ Machining

With only two employees, the entire process at YouniQ is software-driven. This enables fast, cost-effective production without human errors. While a six-week lead time is standard in the market, YouniQ delivers parts within two working days. Customers upload their 3D CAD models and receive a digital quote within an hour based on machine data and required materials. The expected final output is available for immediate download and verification in the assembly as a 3D model. YouniQ primarily serves competitors needing quick parts for their clients.

Business Challenges

YouniQ holds a clear vision: minimising clicks by limiting human intervention from quoting to invoicing and programming. The innovative minds behind YouniQ sought software capable of achieving this, explored additional modules needed, and questioned the feasibility of their vision. Undertaking creating their entire web interface, they experimented with numerous software packages before discovering that Siemens NX™, renowned for its open and adaptable framework, was the key to fulfilling their vision. The next hurdle, however, was to find a partner that could provide YouniQ with the precise level of support they required.

Keys to Success

The manufacturing landscape is shifting, with batch sizes shrinking, volumes decreasing, and product variations rising. The industry's response has primarily been to automate at the machine level, employing robot cells capable of rapid adaptation. Yet, the programming of these diverse parts remains a crucial step. YouniQ distinguishes itself by making a strategic decision to focus on software automation. Their entire operation is managed through a web portal, and given the reliance on 3D models, traditional methods like faxing 2D drawings are obsolete. This reliance places a heavy emphasis on advanced CAD and CAM software, necessitating a partner with deep expertise, especially in YouniQ's specialised area, and sometimes even requiring custom software modifications. Siemens recognised this need and connected YouniQ with us. As a startup operating on a cost-effective model, YouniQ required innovative solutions. We implemented NX™ CAD and NX™ CAM and expansion modules such as APIs for NX™ Open and the Machining Knowledge Editor. We also ensured that YouniQ's team was fully trained for immediate, effective use of the software. Our CAM user group events provide a platform for customers using this software to connect and learn from each other. We maintain a direct line of communication with Siemens, ensuring that any necessary software adjustments are considered for inclusion in future releases.

Results

The results of these efforts led to remarkable achievements at the very outset of the startup, effectively facilitating its successful launch. With around 80% of tasks being seamlessly automated, YouniQ has achieved an incredibly swift turnaround time of just two days.

Related Cases

%2015%25-5.png)

Elevating Automotive Mould Adaptation with NX™ Integration

Surtechno revolutionized European automotive manufacturing by specializing in mould modifications, leveraging NX CAD/CAM integration for real-time design adjustments, swift testing, and superior quality control, reducing time-to-market and securing a vast client base among leading suppliers.

Read Case >%2015%25-3.png)

Revolutionizing Design with Siemens NX™ Integration

Pilipili, an industrial design agency, used Siemens NX™ to overcome software limitations, enabling them to create intricate designs, streamline parametric aspects, and achieve remarkable efficiency, resulting in shorter project timelines and enhanced ability to tackle complex design challenges effortlessly.

Read Case >