Get a 30 Day Trial

Experience Plant Simulation with a free trial today.

REQUEST A FREE PRODUCT GUIDE

Get Product Guide

Learn more about Tecnomatix Plant Simulation by exploring our downloads.

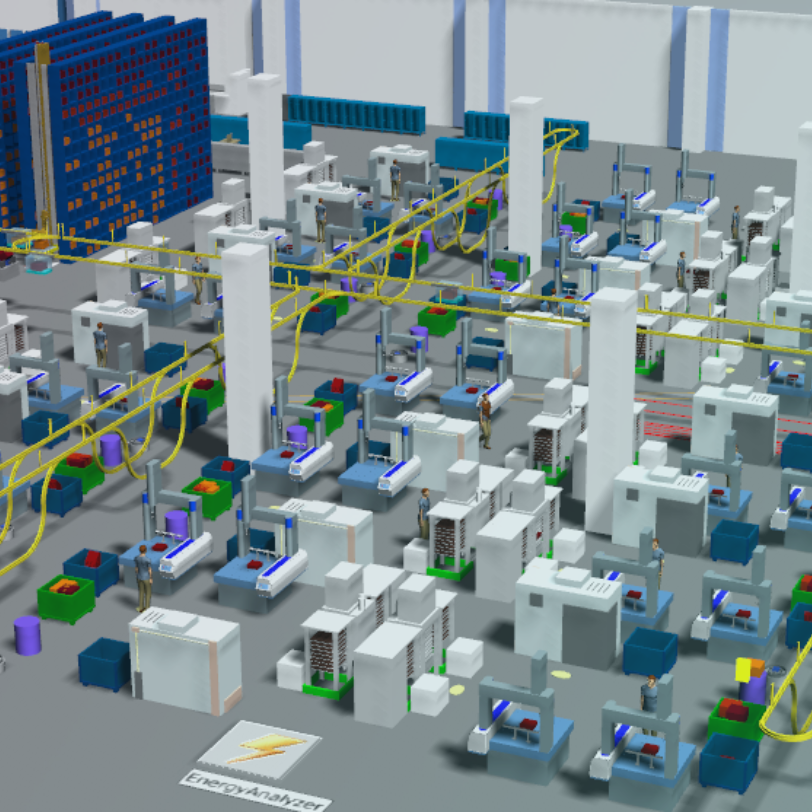

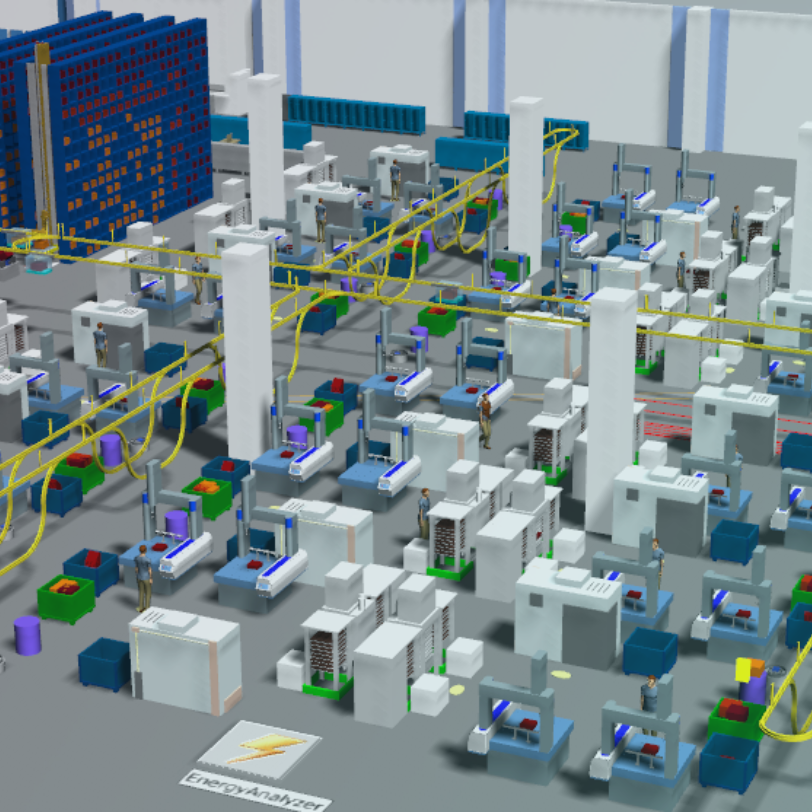

Plant Simulation provides real-time simulation capabilities, enabling the identification of bottlenecks and the validation of changes without interrupting actual operations.

Plant Simulation offers an extensive range of tools for creating detailed, layered models of production systems, facilitating in-depth analysis.

Plant Simulation is scalable, adept at simulating everything from small systems to entire production facilities, making it suitable for businesses of all sizes.

Plant Simulation enables you to visualise your processes in both 2D and 3D, and also offers immersive experiences through virtual reality.

NX hosts a suite of creativity tools that enable design freedom and innovation, allowing you to bring unique ideas to life throughout the product development process.

Plant Simulation integrates seamlessly with other solutions from the Siemens DISW portfolio.

| NX MACH Designer |

NX Layout |

NX MACH 1 Design |

NX MACH 2 Product Design |

NX Cool Shape Design |

NX MACH 3 Product Design |

NX MACH 3 Industrial Design |

|

|---|---|---|---|---|---|---|---|

| Feature category | |||||||

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

Experience Plant Simulation with a free trial today.

Use Tecnomatix Plant Simulation to optimise real-world processes, accommodating variables such as product mix, batch sizes, and operational nuances. Enhance productivity by eliminating bottlenecks and reducing inventory levels. Leverage tools like OEE, Sankey, and Gantt charts for insightful, data-driven decisions.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

Virtual commissioning with Tecnomatix Plant Simulation facilitates pre-launch testing of automation systems, ensuring seamless real-world integration. By simulating controls and operations, it identifies issues early, reduces setup time, and ensures a smooth start to production.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

Experience Plant Simulation with a free trial today.

Use Tecnomatix Plant Simulation to optimise real-world processes, accommodating variables such as product mix, batch sizes, and operational nuances. Enhance productivity by eliminating bottlenecks and reducing inventory levels. Leverage tools like OEE, Sankey, and Gantt charts for insightful, data-driven decisions.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

Virtual commissioning with Tecnomatix Plant Simulation facilitates pre-launch testing of automation systems, ensuring seamless real-world integration. By simulating controls and operations, it identifies issues early, reduces setup time, and ensures a smooth start to production.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

Discover how Oerlikon Eldim (NL) B.V. revolutionized their approach to production efficiency using Discrete Event Simulation. By creating a digital twin of their automated robotic workcell, they gained unprecedented insights into dynamic production factors, optimized resource allocation, and improved communication with management. Witness their journey towards smarter decision-making and resource optimisation in the high-tech manufacturing landscape.

%2015%25-18.png)

In the dynamic world of confectionery, Mr. Mallo stands tall as a European marshmallow pioneer since 1907. Seeking expansion while maintaining quality and cost-effectiveness, the company incorporated product lifecycle management to revolutionise their approach to production. Through simulation-driven strategies, Mr. Mallo redefined their manufacturing landscape, optimising operations, and achieving remarkable efficiencies.

Tecnomatix Plant Simulation is a software tool for simulating, visualising, and analysing production systems and logistics processes. It helps optimise material flow and resource utilisation, enhancing overall plant performance.

Virtual commissioning in Plant Simulation enables the connection of a simulation model to control systems like PLCs or MES. This allows for the testing and optimisation of process controls before physical implementation, saving time and reducing risks.

Yes, Tecnomatix is designed to manage complex production systems. It facilitates detailed modelling of intricate processes and systems to enhance efficiency and productivity across all operational levels.

While Tecnomatix is user-friendly, new users can benefit from training to fully leverage all its features. We offer comprehensive training programs to help users maximise the software’s potential.

We offer robust support for Plant Simulation users through our in-house support desk, providing technical assistance. Additionally, our team of consultants can offer further support through coaching, training, and co-development of models.